DDMRP in APO PPDS Now

ADDV Planner brings the full benefits of DDMRP directly to companies using SAP® APO PPDS. Our solution provides all the necessary functionality to implement the methodology and is officially recognised by the Demand Driven Institute.

You do not need to wait for S/4HANA to reduce inventory, improve customer service, and protect your production process from the Volatility, Uncertainty, Complexity, and Ambiguity of the new VUCA world.

The product roadmap also includes a future extension to support the Demand-Driven Operating Model (DDOM) functionality. PPDS’s advanced scheduling and capacity planning functionality provides a perfect platform for implementing DDOM.

Smooth Migration to S4HANA

With a future-proof roadmap, we ensure your investment is protected. We are actively porting the solution to S/4HANA Advanced Planning (ePPDS).

Because ADDV Planner’s core functionality is consistent across platforms, migrating your planning will be a straightforward technical migration. This means you can upgrade to ADDV Planner for S/4HANA with no new data collection, no user retraining, and no complex change management.

By decoupling your DDMRP implementation from your S/4HANA migration, you can avoid adding pressure to an already challenging project. This approach significantly reduces risk and ensures your critical DDMRP benefits aren’t postponed or deprioritised during a complex transition.

ADDV Planner Features at a Glance

Full-Featured and By The Book

ADDV Planner has been designed and developed to implement the full range of DDMRP features, while closely following the presentation of these features in the seminal book by Smith and Ptak.

At the same time, ADDV Planner leverages the rich and time-tested functionality of SAP Production Planning and Detailed Scheduling (PPDS).

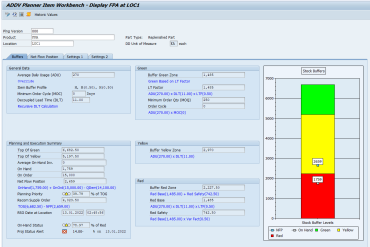

Planner WorkBench (PWB) Item

A central transaction to monitor the DDMRP situation of a product location.

The transaction is used to maintain the parameters that control the item’s behaviour.

It also displays all calculations, proposed procurement, and alerts related to the buffer point, with a layout as close as possible to the one depicted in the book.

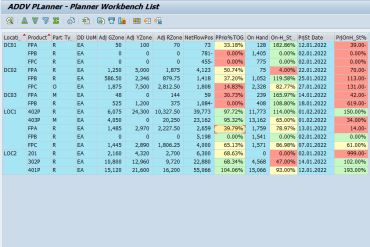

Planner WorkBench (PWB) List

A flexible report that shows all the current DDMRP values for the product-location.

Different layouts are used to display groups of fields for different uses (General status, ADU calculation, NFP, etc.).

As it includes priority position and alerts, it points the planner to the materials that require attention. Clicking the line displays the PWB Item transaction for the product location.

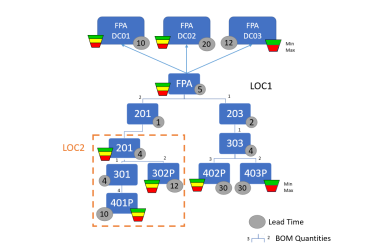

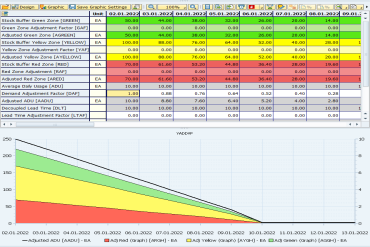

DDMRP Buffers

Buffers are positioned in the network by defining the part as non-buffered or buffered (Replenished, Max-Min, or Replenished Override).

Buffers are constantly recalculated to reflect the current ADU and any change in parameters.

Time series adjustment factors can be used to preempt known changes in the product location situation.

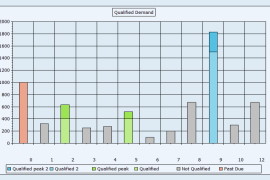

Net Flow Position

After calculating qualified demand directly from the system in a dual horizon/threshold approach, the NFP and recommended supply are determined.

Simulation

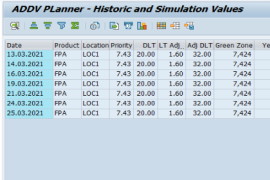

A simulation tool that projects – in figures and graphically – the system response to real or simulated demand. The simulation can be executed daily or for a specified range of days.

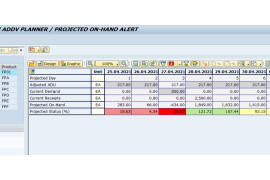

Alerts

All alerts recommended by the methodology to monitor DDMRP execution are provided, as well as ADU alerts, which are used to detect unexpected changes in demand.

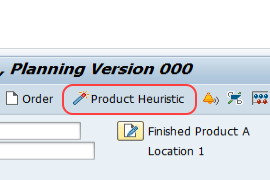

DDMRP Heuristics

A custom heuristic logic that, based on the material’s NFP, generates a planned order for the recommended supply quantity, either interactively or as a background job.

Buffer Projection

All future time-dependent adjustment factors can be maintained, and the buffer projection can be simulated. The ADDV planner uses the saved value for the current date in calculations.

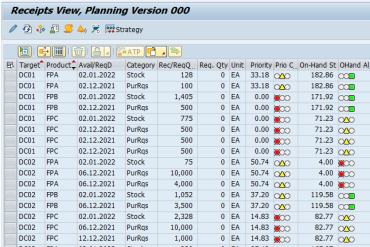

Buffer Status Visibility in RRP* Transactions

DDMRP-relevant values are visible as custom fields in RRP transactions (product, receipt, and requirement views), providing a direct way to view and set priorities for production and purchase.

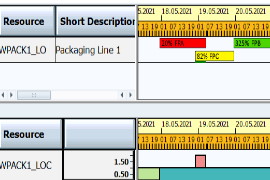

Buffer Status Visibility in the Planning Board

Schedule operations with DDMRP priority position information (colours and figures) displayed on the planning board.

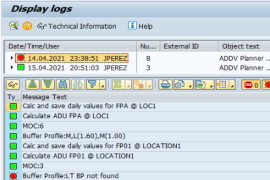

Calculation and Simulation Logs

Full traceability on the applications log of DDMRP decisions and calculations during simulation runs and daily updates.

Most calculation formulas are also detailed along with their resulting value in the PWB item transaction.

Data Tools and Background Jobs

Predefined tools to download and upload ADDV Planner data.

Additional programs to run in the background, performing daily calculations (ADU, Buffers, NFP, etc.)

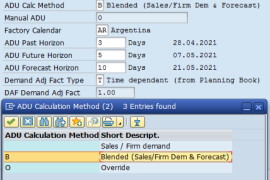

Settings and Profiles

Configure the DDMRP behaviour of each product location with the full range of the methodology options and parameters.

Settings are defined by plant defaults, using profiles or individually.

Data for Metrics and Analytics

Historical data is collected for DDMRP daily settings and calculations, allowing it to be extracted for Analytics and used as the base for DDS&OP.

The projected values of the last simulation can also be saved for further analysis.

Consulting and Customization

We offer consulting services to install and integrate the solution with your existing installation. We also provide functional and technical training to your in-house resources.

We can also customise the solution for specific requirements.

Testimonials of Previous Work and Solutions by Joaquin

“He will consider, advise, debate, propose, agree, test, train and implement the solution. Our company has been using some of his deliverables for years now. He assisted in enhancements around planning and scheduling, which were helpful to our productivity and process. I would work with him again without reservation.”

Dave Caldwell

Group Planning Director, GTS and Warehousing at CoatS .

“Joaquin demonstrated a great depth of functional technical know-how and a very thorough and conscientious approach, putting in the extra mile to meet demanding requirements or deadlines. He is a strong team player and sensitive to relationships throughout the team, I would recommend highly.”

Jim Houghton

Director at Olivehorse Ltd

.

“Joaquin, thank you for your outstanding contribution and hard work on implementing the APO Change Requests. You really did a difference with your commitment, collaboration and your deep knowledge in APO planning.

You were always open to support, taking initiative, proposing solutions and providing timely feedback.”

Alexandra Tödter

Business Process Manager (EMEA) at AstraZeneca

“The technical challenges were also considerable, yet Joaquin always drove us to the right solution, and he was capable of thinking outside the box when it was necessary. A solid, reliable, technically gifted colleague I would have no hesitation in recommending or re-employing if the need arose.”

.

Paul Millward

Head of Supply Chain Planning at Asahi UK

.

“I was impressed with how quickly he entered into our requirements. The task was not a standard one and required a thorough investigation of specialised statistical books and papers. Joaquin successfully completed the project, and all this was done in a very short term. I can recommend him as a brilliant professional.”

Evgeni Iliev

Business Process Leader – Demand Planning at Coca-Cola Hellenic

“He showed detailed attention and complete understanding of business requirements and designed solutions to meet the business needs. He investigates and provides alternative solutions and recommendations when we are faced with challenges.”